Standard pipe schedule charts are essential references for pipe dimensions, including outside diameter, wall thickness, and weight. They ensure compliance with ASME B36.10/B36.19 standards, crucial for engineering and plumbing applications.

1.1 What is a Standard Pipe Schedule Chart?

A standard pipe schedule chart is a reference document detailing pipe dimensions, including outside diameter, wall thickness, and weight per foot. It follows ASME B36.10/B36.19 standards, covering various schedules like Schedule 40, Schedule 80, and XXS. The chart provides precise measurements for nominal pipe sizes, ensuring consistency in engineering and plumbing applications.

1.2 Importance of Pipe Schedule Charts in Engineering and Plumbing

Pipe schedule charts are vital for ensuring safety and structural integrity in piping systems. They provide standardized dimensions, enabling engineers and plumbers to select the correct pipe size and wall thickness for specific applications. This ensures compliance with industry standards, optimizes material usage, and supports the design of efficient systems in industries like oil, gas, and water supply.

Understanding Pipe Schedules

Pipe schedules are standardized classifications for pipe wall thickness, ensuring strength and durability. They include nominal size, outside diameter, and weight, crucial for engineering and plumbing systems.

2.1 Nominal Pipe Size and Outside Diameter

Nominal pipe size (NPS) refers to the pipe’s diameter in inches, while the outside diameter (OD) is the actual measurement. For example, a 1/2-inch NPS pipe has an OD of 0.405 inches. This information is critical for selecting the correct pipe size and ensuring compatibility with fittings and connections, as detailed in standard pipe schedule charts.

2.2 Schedule Numbers and Their Significance

Schedule numbers (e.g., 10, 40, 80) indicate a pipe’s wall thickness relative to its nominal size. Higher schedules mean thicker walls, providing greater strength and pressure resistance. They are standardized to ensure uniformity in pipe manufacturing and application, as outlined in ASME B36.10 and B36.19 specifications. This standardization is vital for engineering and plumbing systems to maintain safety and reliability.

2.3 Wall Thickness and Its Impact on Pipe Strength

Wall thickness is a critical factor in determining pipe strength and durability. Thicker walls, as indicated by higher schedule numbers, provide greater resistance to internal pressure and external stress. This ensures the pipe can withstand harsh conditions and maintain its structural integrity over time, making it essential for safe and reliable piping systems in various industries.

Standard Pipe Schedule Charts

Standard pipe schedule charts, like ASME B36.10 and B36.19, provide detailed dimensions for pipes, including sizes, schedules, wall thickness, and outside diameters, ensuring precise engineering specifications.

3.1 ASME B36.10 and B36.19 Standards

ASME B36.10 and B36.19 standards provide dimensional specifications for welded and seamless pipes. B36.10 covers carbon and alloy steel pipes, while B36.19 focuses on stainless steel. These standards ensure uniformity in pipe manufacturing, detailing nominal sizes, outside diameters, wall thicknesses, and weights for various schedules, essential for accurate engineering and installation in industrial and plumbing systems globally.

3.2 Pipe Sizes and Schedules Available in the Chart

Standard pipe schedule charts include a wide range of pipe sizes, from 1/8 inch to 40 inches, covering various schedules such as Schedule 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, and extra-strong (XS) and double extra-strong (XXS). Each size specifies outside diameter, inside diameter, wall thickness, and weight per foot, ensuring precise engineering and installation applications across industries.

Applications of Pipe Schedule Charts

Pipe schedule charts are essential for oil and gas, plumbing, and water supply systems, ensuring proper pipe selection for optimal performance and safety.

4.1 Use in Oil and Gas Industries

In the oil and gas sector, pipe schedule charts are critical for selecting pipes that withstand extreme conditions. They ensure pipes meet ASME standards, providing details on wall thickness and strength to handle high pressure and corrosive substances. This ensures system integrity and prevents failures, which are vital for operational safety and efficiency.

4.2 Application in Plumbing and Water Supply Systems

Pipe schedule charts are vital in plumbing and water supply systems for selecting pipes that meet specific pressure and flow requirements. They provide details on Nominal Pipe Size (NPS), outside diameter (OD), and wall thickness, ensuring pipes are durable and resistant to water pressure. This ensures efficient water distribution and longevity of the system, whether for residential or large-scale applications.

How to Read a Pipe Schedule Chart

Understanding the columns and rows is key. Identify Nominal Pipe Size (NPS), outside diameter (OD), and wall thickness for various schedules, ensuring accurate pipe selection for specific applications.

5.1 Understanding the Columns and Rows

A standard pipe schedule chart organizes data in columns and rows. Columns typically list Nominal Pipe Size (NPS), Outside Diameter (OD), and wall thickness for various schedules. Rows provide specific measurements, allowing users to quickly find dimensions for their needs. This structured format ensures clarity and ease of use when selecting pipes for engineering or plumbing projects.

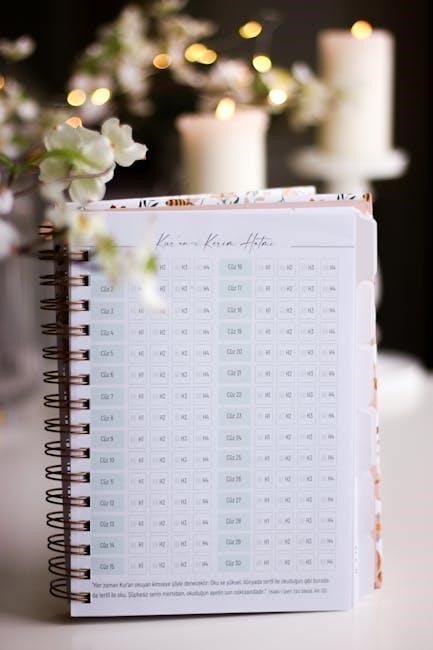

5.2 Example of a Sample Pipe Schedule Chart

A sample pipe schedule chart typically includes columns for Nominal Pipe Size (NPS), Outside Diameter (OD), Wall Thickness, and Schedule Number. For example, a 1-inch NPS pipe has an OD of 1.315 inches with a Schedule 40 wall thickness of 0;133 inches. Such charts provide quick references for engineers to select the correct pipe dimensions for specific applications, ensuring safety and efficiency in system design.

Comparison of Different Pipe Schedules

Pipe schedules vary by wall thickness and pressure capacity. Schedule 40 is standard for many applications, while Schedule 80 offers thicker walls for higher pressure demands.

6.1 Common Schedules vs. Special Schedules

Common schedules like Schedule 40 and Schedule 80 are widely used for standard applications due to their balanced cost and strength. Special schedules, such as Schedule 160 and XXS, are designed for high-pressure or heavy-duty environments, offering thicker walls and greater durability, making them ideal for industrial or specialized piping systems where safety and longevity are critical.

6.2 Schedule 40 vs. Schedule 80: Key Differences

Schedule 40 and Schedule 80 pipes differ primarily in wall thickness and application. Schedule 40 has a thinner wall, making it lighter and more cost-effective for general plumbing. Schedule 80, with its thicker wall, offers greater strength and is ideal for high-pressure or heavy-duty environments, making it more durable but also heavier and more expensive.

Selecting the Right Pipe Schedule

Selecting the right pipe schedule involves considering factors like pressure, fluid type, and application requirements. Always refer to ASME B36.10/B36.19 standards for accurate sizing and material compatibility.

7.1 Factors to Consider for Pipe Schedule Selection

When selecting a pipe schedule, consider the operating pressure, fluid type, and application environment. Also, evaluate pipe material, installation costs, and long-term maintenance needs. Ensure compliance with industry standards like ASME B36.10/B36.19 for accurate sizing and material compatibility. Proper selection ensures system efficiency, safety, and durability.

7.2 Common Uses of Different Pipe Schedules

Schedule 40 is widely used for general plumbing and water supply systems due to its cost-effectiveness and durability. Schedule 80 is preferred in high-pressure environments like industrial plants. Schedule 10 is ideal for low-pressure applications, while Schedule 120 and above are used in heavy-duty industrial settings. Each schedule is selected based on specific requirements to balance cost, durability, and performance for optimal system operation.

Importance of Pipe Schedule in Piping Systems

Pipe schedules ensure ASME B36.10/B36.19 compliance, guaranteeing safety and structural integrity. They help in selecting the right pipe thickness for pressure resistance, optimizing cost and efficiency in piping systems.

8.1 Ensuring Safety and Structural Integrity

Using ASME B36.10/B36.19 standards, pipe schedules ensure pipes meet safety requirements. Proper wall thickness prevents failure under pressure, while correct materials ensure durability. This compliance guarantees systems are reliable and structurally sound, minimizing risks of leaks or collapses, especially in high-pressure environments. Accurate pipe scheduling is critical for maintaining the integrity and longevity of piping systems across industries.

8.2 Cost and Efficiency Considerations

Using a standard pipe schedule chart helps balance cost and efficiency by selecting pipes that meet specific pressure and flow requirements without over-specifying. Thinner walls reduce material costs, while thicker walls ensure durability. Proper scheduling avoids unnecessary expenses and optimizes system performance, ensuring long-term reliability and cost-effectiveness in industrial and plumbing applications;

Key Specifications in a Pipe Schedule Chart

A standard pipe schedule chart includes outside diameter, inside diameter, wall thickness, and weight per foot. These specs ensure precise pipe selection for system design and functionality requirements.

9.1 Outside Diameter and Inside Diameter

The outside diameter (OD) and inside diameter (ID) are critical measurements in pipe specifications. OD refers to the total width of the pipe, including the wall thickness, while ID is the inner space for fluid flow. These dimensions are provided in inches and millimeters, ensuring precise sizing for engineering and plumbing applications. Accurate OD and ID measurements are vital for maintaining structural integrity and flow efficiency in piping systems.

9.2 Wall Thickness and Weight per Foot

Wall thickness determines a pipe’s strength and durability, while weight per foot indicates material usage. These values vary across schedules, with thicker walls in higher schedules providing greater resistance to pressure. Charts specify these measurements in inches and pounds, aiding in material selection and cost estimation for projects, ensuring pipes meet both functional and budgetary requirements effectively.

Popular Formats of Pipe Schedule Charts

10.1 PDF Versions for Easy Reference

PDF versions of pipe schedule charts are widely used for their accessibility and ease of printing, offering detailed pipe specifications and standards like ASME B36.10.

PDF versions of pipe schedule charts are popular due to their portability and ease of use. They provide detailed specifications, including ASME B36.10 standards, and are easily searchable. PDFs are ideal for offline access and printing, making them a convenient reference for engineers and plumbers. They often include comprehensive tables covering various pipe schedules and are regularly updated for accuracy.

10.2 Online Interactive Pipe Schedule Tools

Online interactive pipe schedule tools offer dynamic access to pipe dimensions and specifications. They provide real-time calculations and visualizations, enabling users to filter by NPS, schedule, and material; These tools enhance efficiency in piping projects, allowing for quick comparisons and accurate data retrieval. They are particularly useful for engineers and plumbers needing precise information without downloading PDF charts.

Best Practices for Using Pipe Schedule Charts

Best practices include verifying standards, ensuring chart accuracy, cross-referencing specifications, staying updated, and ensuring team consistency to meet project requirements effectively.

11.1 Verifying Standards and Specifications

Verifying standards ensures compliance with ASME B36.10M and B36.19M for accurate pipe dimensions. Always cross-reference specifications with the latest revisions to avoid errors. Check nominal pipe size, outside diameter, wall thickness, and weight per foot against the chart. This ensures consistency and reliability in piping systems, meeting project requirements and safety standards effectively.

11.2 Regular Updates and Revisions

Regular updates to pipe schedule charts ensure compliance with the latest ASME B36.10M and B36.19M standards. Revisions often include changes to nominal pipe sizes, wall thickness, and weight specifications. Staying informed about updates is crucial for maintaining accuracy in piping systems. Always refer to the most recent charts to ensure reliability and safety in engineering and plumbing projects.

Standard pipe schedule charts are indispensable tools for precise pipe sizing and specifications. They ensure compliance with industry standards, enhancing safety, efficiency, and reliability in various applications.

12.1 Summary of Key Points

Standard pipe schedule charts provide detailed dimensions, including outside diameter, wall thickness, and weight per foot. They adhere to ASME B36.10/B36.19 standards, ensuring consistency in pipe sizing. These charts are vital for engineers and plumbers to select the right pipes for specific applications, optimizing safety, durability, and efficiency in systems like oil, gas, and water supply.

12.2 Future Trends in Pipe Scheduling

Future trends in pipe scheduling include the adoption of digital tools for real-time calculations and interactive charts. Advanced materials like PVC and HDPE are gaining prominence for durability. Additionally, 3D printing may revolutionize pipe manufacturing, enabling custom sizes. These innovations aim to enhance efficiency, sustainability, and precision in piping systems, aligning with evolving industry standards and environmental demands.